Categories

- Hygienic PVC Cladding Blog | Installation Tips & Industry Insights

- PETG Sheet Blog | Fabrication Tips, Applications & Product Insights

- Acrylic Perspex Blog | Tips, Ideas & Guides from Access Plastics

- Multiwall Polycarbonate Sheet Blog | Guides, Tips & Inspiration

- Solid Polycarbonate Sheet Blog | Insights, Tips & Project Ideas

-

How Solid Polycarbonate Sheets Can Benefit Your Projects

September 25 2024 -

Cleaning Solid Polycarbonate Sheets

February 05 2024 -

PVC Cladding Installation Guide

November 01 2023 -

PLEXIGLAS® - Building a Balcony Privacy Screen

October 31 2023 -

Cutting PLEXIGLAS sheets

October 13 2023 -

Installing Secondary Glazing

September 22 2022 -

Cutting Polycarbonate Sheets

February 23 2021 -

MarPETg FS flat sheet

February 02 2021

Cutting PLEXIGLAS sheets

Machines used to process metal and wood can usually also be used for cutting PLEXIGLAS®. Scribing knives can also be used to cut PLEXIGLAS®. Check out our video to learn how to cut acrylic glass sheets with a circular hand saw, jig saw or a scribing knife to achieve perfect cuts.

Materials and tools – what you need for cutting PLEXIGLAS®

- 1. Manual router

- 2. Jigsaw with appropriate blade (or, for thin sheets, a scriber)

- 3. Screw clamps

- 4. Guide track

- 5. Circular hand saw with blade appropriate for PLEXIGLAS®

- 6. Plane

- 7. Folding ruler

- 8. Permanent marker or grease pen

- 9. Draw Blade, plane, or manual router; alternatively, file or sandpaper

Cutting PLEXIGLAS®: Instructions for precise cuts

1. Leave the masking film on the sheet

To protect the surface during cutting, leave the masking film on the sheet as long as possible.

2. Draw the line

Before you start cutting, draw the line along which you want to. Permanent markers or grease pens work well.

3. Secure the sheet on a level base

Lay the sheet on a level base. The part that you want to split off should project beyond the edge of the base. Secure the material with clamps or screw clamps, for example. Important: Clean the base beforehand so that no sharp-edged parts that could damage the sheet project from it.

4. Use a guide track

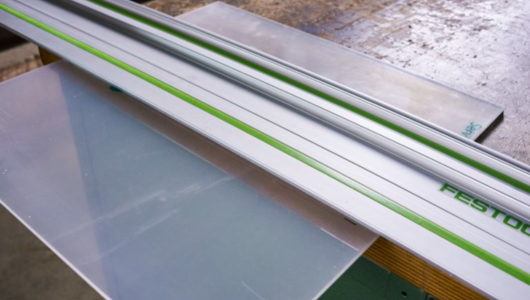

For accurate cutting it is best to use a guide track.

5. Drill a hole when cutting an angle

For clean angles it is recommended to drill a hole at the intersection of the lines.

6. Set rotational speed and feed rate

Set the rotational speed and feed rate before sawing. Recommended settings for sawing PLEXIGLAS® with circular hand saws or jigsaws are given in the Machining PLEXIGLAS® brochure. Faulty settings can often be recognized from incrustations or fusion at the cut edge.

7. Sawing

Switch on the saw before guiding it through the acrylic sheet and cut the material carefully, keeping the saw running. Take care to follow the guide track accurately. The blade of a circular hand saw should barely project above the sheet. You can use a vacuum cleaner to remove swarf.

8. Deburr the cut edges

Deburr the cut edges with a scraper, sandpaper, or a file. An electric woodworking plane or manual router may also be used for this purpose. Secure the PLEXIGLAS® sheet in a vice with suitable protective jaws, for example, so that it does not slip during processing.

Tips and additional notes for cutting PLEXIGLAS®

- • Wear hearing protection and safety glasses to avoid injury.

- • Remove the masking film only after completing all the work steps.

- • Use a guide track for straight edges.

- • Before sawing, on a test sample check that the saw blade is suitable and the settings are correct.

- • Note that the cut edge is sharp after cutting.

- • If there is no masking film left on the sheet, apply adhesive tape at the place where you want to cut the PLEXIGLAS®. In this way you will prevent fusion of the material, as well as scratches or breakouts.

We also provide a FREE cut to size service on all PLEXIGLAS sheets (square and rectangle cuts only). Just enter the dimensions required when ordering. Check out our range of PLEXIGLAS acrylic sheets.