How to Cut Multiwall Polycarbonate Sheets: A Step-by-Step Guide

Tools and Materials Needed

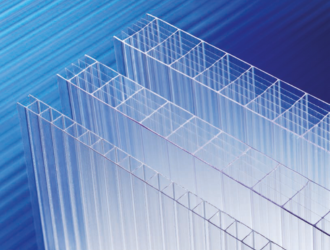

Plastics sheet needed: (6mm, 10mm, 16mm and 25m) Polycarbonate Sheet Multiwall

When cutting multiwall polycarbonate sheets you can use the following:

- Utility Knife: Ideal for scoring and cutting thinner sheets (less than 6mm)

- Circular Saw: Suitable for thicker sheets, Use with a fine-tooth blade designed for cutting plastics or acrylics.

- Jigsaw: Optional tool with a fine-tooth blade that can be used for cutting curves or intricate shapes

Other materials needed:

- Straightedge, Metal Ruler or Measuring Tape: For marking straight, accurate cutting lines.

- Clamps: To hold the sheet in place and prevent movement during cutting.

- Marker or Pencil: For marking the cutting line on the protective film of the polycarbonate sheet.

- Fine-Grit Sandpaper: For smoothing rough edges after cutting.

Safety Gear

- Safety Glasses: To protect your eyes from flying debris.

- Gloves: To protect your hands from sharp edges.

- Dust Mask: Optional, to avoid inhaling plastic particles.

- Hearing Protection: If using power tools, use earplugs or earmuffs to protect your hearing from noise.

Step-by-Step Instructions

Step 1: Preparation:

- Clean the Sheet: Ensure the polycarbonate sheet is clean and free of any dirt or debris. Use a soft cloth or a brush to remove any particles that might interfere with the cutting process.

- Secure the Sheet: If necessary, use clamps or weights to secure the sheet in place to prevent any movement during cutting.

- Prepare the Surface: Place the polycarbonate sheet on a stable, flat surface. Ensure the surface is large enough to support the entire sheet and is free of any obstructions.

Step 2: Measure and Mark

- Mark the Cutting Line:

Clearly define the width and length of the sheets you want. Using a straight edge and a non-permanent marker or pencil, carefully measure and mark the cutting line on the protective film covering the polycarbonate sheet. Ensure the line is straight and precise to achieve a clean cut.

Step 3: Choose the Right Cutting Tool

- The first step in cutting a polycarbonate sheet is to choose the right tool.

- For thin sheets, use a utility knife to score the sheet along the marked line. Make several passes with the knife to deepen the score line.

- For thicker sheets or if you prefer a cleaner cut, you will need a circular saw with a fine-toothed blade, a jigsaw. Ensure the blade is suitable for cutting plastics, as this will prevent the sheet from cracking or chipping during the cutting process. You will also need a straightedge, a tape measure, a marker, and a clamp.

Step 4: Cutting Techniques

- To prevent the sheet from moving while you are cutting, secure it to a work surface using clamps. Ensure the sheet is flat and stable, as this will prevent the blade from wobbling during the cutting process.

- For thin sheets, use a utility knife to score along the marked line. Make several passes to deepen the score line.

- When cutting the sheet with a saw, ensure the blade is spinning at full speed before you start cutting. This will prevent the sheet from cracking or chipping during the cutting process. Slow and steady motion guides the saw along the cutting line. Do not apply too much pressure, which can cause the sheet to crack or chip. If you are using a jigsaw or handsaw, make sure to use a fine-toothed blade and follow the same process.

- Using the handheld cutter, use the steel ruler to guide the blade as you run it down the sheet. Go over the line two or three times to create a definitive groove. Then use the table's edge as leverage to hold pressure on the sheet. It should make a clean break if cut correctly.

Step 5: Finishing Edges

- After cutting the sheet, use a fine-grit sandpaper or a deburring tool to smooth the edges of the cut. This will remove any burrs or rough edges that can be dangerous and cause injury.

- Once you have finished cutting and sanding the sheet, clean it with a soft cloth and a mild soap solution to remove any debris or dust. This will ensure that the sheet remains clear and transparent.

- After cutting, remove the protective film from the polycarbonate sheet

Cutting service

At 365plastics, we offer the possibility to pre-cut the plastic sheets which is convenience and provide precision to our customers. We offer a specialised pre-cutting service for our plastic sheets, ensuring that you receive materials tailored to your exact specifications. Our state-of-the-art cutting technology and experienced team guarantee clean, accurate cuts every time. Whether you need custom sizes for a specific project or the need for bulk orders pre-cut for a project.

We provide a rree cut to size service on our plastic sheets. This involves cutting in square and rectangle shapes only. We do have an in-house plastic fabrications team which can quote you on all other cut shapes or additional specific requirements, please contact us for a quote on 01 8010022 or sales@accessplastics.com

Common Mistakes to Avoid

The common pitfalls when cutting multiwall polycarbonate sheets and how to avoid them, follow these tips for flawless polycarbonate cuts every time.

1. Using the wrong tools:

One of the most critical mistakes is using inappropriate tools for cutting multiwall polycarbonate. Common tools like regular saws or knives can lead to jagged edges and cracking. Instead, use fine-toothed circular saws or jigsaws with blades designed specifically for plastics to achieve clean cuts.

2. Cutting too quickly:

Proper cutting speed is important ... Rushing through the cutting process can cause overheating and melting of the polycarbonate, leading to rough edges and potential damage. Cutting slowly and steadily ensures a smoother finish and reduces the risk of deforming the material.

3. Not measuring accurately:

Inaccurate measurements can result in improperly sized pieces that may not fit correctly in their intended applications. Double-check all measurements before cutting and use a straight edge or guide to ensure precise cuts.

4. Not removing protective film:

Many polycarbonate sheets come with a protective film to prevent scratches. Cutting through this film can make it difficult to remove later and may leave residue on the edges. Remove or peel back the protective film from the cutting area before starting the process.

5. Overlooking cleaning and preparation:

Dust, dirt, and debris on the sheet can interfere with the cutting process and result in a less clean cut. Always clean the sheet thoroughly before cutting to ensure smooth operation and a better finish.

Safety Tips and Precautions

When cutting multiwall polycarbonate sheets, wearing the appropriate safety gear is crucial. Always wear safety goggles to protect your eyes from flying debris and dust. Use gloves to prevent cuts and abrasions, ensuring your hands are shielded from sharp edges. To avoid inhaling fine particles, wear a dust mask, which will help keep your respiratory system safe. If you're using power tools, protect your hearing from noise by using earplugs or earmuffs. By taking these precautions, you can significantly reduce the risk of injury while working.

Additionally, ensure the work area is well-ventilated and free of obstructions. Handle the sheet carefully to avoid scratches or damage. By taking these precautions, you can significantly reduce the risk of injury while working.

Frequently Asked Questions

- What tools do I need to cut multiwall polycarbonate sheets?

Answer: You can use various tools to cut multiwall polycarbonate sheets, including a utility knife for thinner sheets, and a circular saw with a fine-tooth blade for thicker sheets. A straightedge or metal ruler, clamps, and safety gear (gloves, safety glasses) are also recommended. - How do I ensure a straight cut?

Answer: Use a straightedge or metal ruler to mark the cutting line. Clamp the sheet to prevent movement during cutting, and use the ruler as a guide for your cutting tool. - Can I use a jigsaw to cut polycarbonate sheets?

Answer: Yes, a jigsaw with a fine-tooth blade can be used for cutting polycarbonate sheets. Ensure that you use a slow to moderate speed to avoid melting the plastic. - What is the best way to cut thick multiwall polycarbonate sheets

Answer: For thick sheets, a circular saw with a fine-tooth blade is recommended. Ensure the blade is sharp and cut slowly to avoid cracking or damaging the sheet. - How do I avoid chipping or cracking the sheet while cutting?

Answer: Use a sharp blade and cut at a slow, steady pace. Supporting the sheet on both sides close to the cut line can also help minimize vibration and potential damage. - Do I need to remove the protective film before cutting?

Answer: It's usually best to leave the protective film on during cutting to prevent scratches. Remove it after you've finished cutting and handling the sheet. - How do I finish the edges after cutting?

Answer: If the edges are rough, you can sand them lightly with fine-grit sandpaper. This will smooth out any irregularities and make the edges safer to handle. - Is it safe to cut polycarbonate sheets indoors?

Answer: Cutting polycarbonate sheets can produce small plastic particles and dust. It's best to cut in a well-ventilated area or outdoors. Wear safety glasses and a dust mask to protect yourself. - Can I use a laser cutter for polycarbonate sheets?

Answer: While it is possible to use a laser cutter for polycarbonate sheets, it requires specialized equipment and settings to avoid melting the plastic. It's typically easier and more accessible to use manual cutting tools.