Installing Secondary Glazing

The Eco Secondary Glazing System uses plastic panels to block drafts and noise over existing single glazed or double glazed windows. Eco secondary glazing will make your home warmer in winter and cool and comfortable in summer, while greatly reducing your heating bills. It is also effective in eliminating noise and condensation on the inside of windows. And don't worry, it doesn’t affect the window’s functionality. Whether it’s a sliding, fixed or hinged window, you can still open and close them as you did before.

Ecoglaze Secondary Glazing is made from premium quality, acrylic sheet. All materials are fully recyclable. Ecoglaze is fitted to the inside of the existing window, and held in place using our magnetic system. This system traps a layer of still air between the pane of glass and the Ecoglaze Secondary Glazing. This trapped airspace will reduce the rate of heat loss, and also act as a buffer to reduce sound transmission. Ecoglaze can double glaze your existing windows for a fraction of the cost when compared with replacement double glazed windows, and will still provide you with the benefits of standard double glazing.

What Equipment is needed?

- 1. We have a measuring tape and we recommend that you measure in metric millimetres.

- 2. Secondly we have a strong snips and scissors, for cutting the magnetic tapes.

- 3. A pencil and notepad, just to take your measurements down and also maybe to mark on the window frame, in pencil where you are going to apply the steel strip.

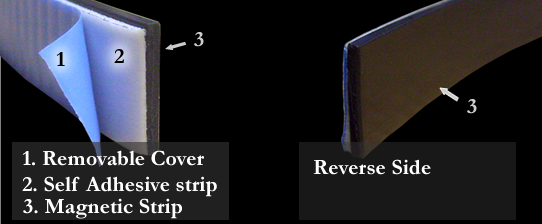

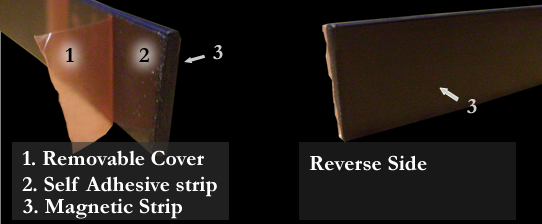

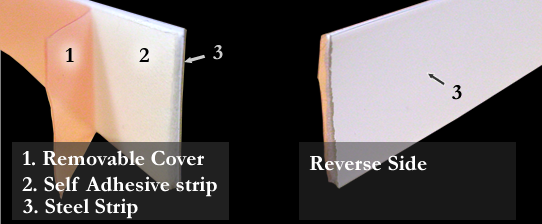

- 4. Magentic Tape Kit – 15m in each kit, 20mm wide, 1.5mm overall thickness. It is made up in 2 parts, a steel magnetic strip and a foam magnetic strip.

- 5. Finally a cloth, just to rub down on the frame when we have applied the magnetic strip, just to ensure we have a nice smooth even surface.

Measuring the window.

- So the first thing we need to do is take a clear and accurate measurement of the window, both width and height. Remember the strip is 20mm wide, so you must allow for 20mm on the flat section of the window frame.

- Mark 20mm in on that and run the tape straight across into the corner, allowing another 20mm on that side.

- Repeat the process for the height of the window frame. Again allow for the 20mm on the flat of the frame.

- When you have measured all the required window sizes, proceed to the 365plastics website and select the nearest oversized sheet from the list of sizes available. Enter in your required cut to size panel and we will cut to your exact size.

INSTRUCTIONS FOR FITTING SECONDARY GLAZING

Please read these instructions before you begin the installation.

If you have any questions please feel free to contact us either by email at sales@365plastics.ie or by phone on 01 8010022

1. Each glazing sheet is protected on both surfaces by a self-adhesive film. Leave these protection films on the sheet until you are ready to fit it – it will protect the sheet surface from scratches

2.The self-adhesive magnetic tape comes in two types – Type “A” and Type “B”. Type “A” is magnetic and has a BROWN surface and Type “B” IS WHITE STEEL. Type “A” MUST be matched to Type “B” – or you will have no magnetic effect. The magnetic tape is easily cut with scissors or a craft knife.

3.The adhesive side of the magnetic tape is covered by a film. This film should be removed before applying the tape to the surface of the glazing panel or to the window frame. When you are ready to fit the secondary glazing:

4.First check that the glazing sheet is the correct size by placing it temporarily on the window. Hopefully, you have ordered the correct size of sheet. If not, it can be trimmed to the correct size using a fine-toothed wood saw. Make sure that the saw is sharp and that the sheet is well supported during any cutting operation.

a. On one side of the sheet peel back the 4 edges of the surface protection film by 3 to 5 cm. This will ready the panel for applying the magnetic tape.

b. Cut 4 lengths of Type ”A” magnetic tape. Remove the film backing on the tape and fit it to the outer edge of the sheet so that there is a continuous strip of tape around the edge of the sheet. DO NOT OVERLAP THE TAPE – a uniform thickness is needed to give a good seal to the window frame. The magnetic tape can easily be cut with a pair of scissors or a sharp craft knife.

c. Next, cut 4 pieces of Type “B” STEEL tape to the same lengths as those used in “c” above. PLACE THE TYPE “B” TAPE ON TOP OF THE TYPE “A” SO THAT THE TAPES ARE HELD TOGETHER BY MAGNETIC ATTRACTION.

d. CLEAN THE SURFACE AROUND THE WIDOW FRAME ONTO WHICH YOU WILL BE STICKING THE MAGNETIC TAPE, USING METHYLATED SPIRITS OR SIMILAR DEGREASER.

e. Remove the surface protection film from the side of the sheet having the magnetic tape. DO THIS SLOWLY TO PREVENT STATIC! Also remove the film backing from the Type “B” steel tape.

f. Line up the panel against the frame using supports where possible – or better still – an extra pair of hands!

g. When you are sure you have the panel exactly where you want it, apply light pressure only in case the panel needs to be repositioned.

h. When you are positive your panel is exactly where you want it, run round the edge applying as much pressure as possible. You can do this simply with your fingers – or you can use a narrow wallpaper roller.

5.Finally, remove the surface protection film from the outside of the sheet. If you do this reasonably slowly it will minimise any static electricity, which can attract dust. However, if this does happen, clean the surface using some furniture polish such as Pledge or similar. Use a SOFT cloth – microfibre is ideal. The polish will remove the static and the soft, non-abrasive cloth will get rid of the dust.